Two Clamp QOC

Brand Lianerdun

Product origin Mudanjiang

Delivery time 30-60days

Supply capacity 100Pcs/Month

Convenience of use:

1.Short opening and closing time: due to its structural characteristics, the opening and closing time of the two clamp-type quick opening closure is significantly shorter than that of the traditional blind, which makes the material loading and unloading more convenient and quicker.

2.Fewer operators: the opening and closing operation can be completed by a single person, and other personnel can monitor it, which reduces the dependence on manpower in the operation process.

Scope of application

1.Wide range of applications: applicable to high, medium and low pressure and other different requirements, as well as a variety of installation modes, including vertical and horizontal installation, making its wide range of applications.

2.Variety of applicable media: applicable to a variety of media such as natural gas, increasing its practicality and market demand.

Durable

1.Long-term service life: 30 years of service life, reflecting its durability and reliability.

2.Strong seismic performance: the degree of crack resistance reaches 7 degrees, which can effectively resist the impact of natural disasters such as earthquakes.

Download

Two Clamp Quick Opening Closure

Two Clamp Quick Opening Closure Product Information

Product Information | |

QOC Nominal Size | From 4″ to 78″ |

QOC Design Code | ASME VIII Div. 1 |

QOC Design Pressure Rating | Up to 100MPa |

QOC Design Temperature (min/max) | -46°C / +350°C |

QOC Orientation | Horizontal/Vertical |

Gasket Seal | O-Ring/Lip seal |

Design Conditions | |

Design Code ASME VIII Div. 1 | Yes |

Code stamped | Yes |

Vassel Wall Thickness | Acc. to the vessel |

Principal Materials | |

Hub Material | Carbon steel/Stainless Steel/Duplex/Super Duplex |

Door Material | Carbon steel/Stainless Steel/Duplex/Super Duplex |

Gasket Seal | NBR/HNBR/VITON |

Hinge/Davit Material | Carbon Steel / Stainless Steel |

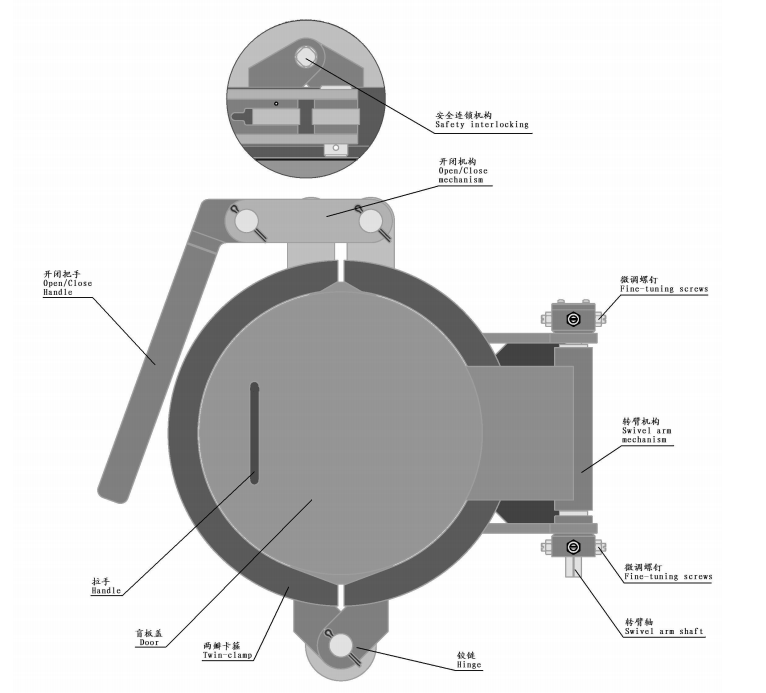

Two Clamp Quick Opening Closure Opening Operation

1)Before opening the door,the pressure inside the equipment must be ensured to be zero,and safe operating procedures must be strictly followed.

2)unscrew the safety bolts on the Locking mechanism. If there is residual pressure in the equipment, should stop removing the safety bolt immediately and recheck the equipment pressure again. Ensure that the inside pressure relief is complete (the pressure gauge pointer on the equipment returns to zero) before unscrew the safety bolt and locking mechanism.

3) Trigger the opening and closing handles , so that the double yoke clamps slowly rise to the maximum, to reach the end closure can be opened state, hold the handle to open the end closure.

In addition, after understanding the above, considering that you may also have further interest in the specific application and operation of the Quick Opening Closure, the following are some other considerations and information:

1.In actual use, it should be ensured that the indications of the gauges on the vessel in which it is located are normal and that there is no leakage from the connection parts.

2.Pressure check should be carried out before the operation of the opening and closing blind, to confirm that the pressure indication value of the inner chamber of the cylinder is back to zero, in order to avoid the danger in the operation.

3.Use special explosion-proof tools for operation to prevent accidents caused by improper operation.

4.It is recommended to check and maintain the quick-opening blind regularly to keep it in good working condition and prolong its service life.