Double Yoke Clamp QOC

Brand Lianerdun

Product origin Mudanjiang

Delivery time 30-60days

Supply capacity 100Pcs/Month

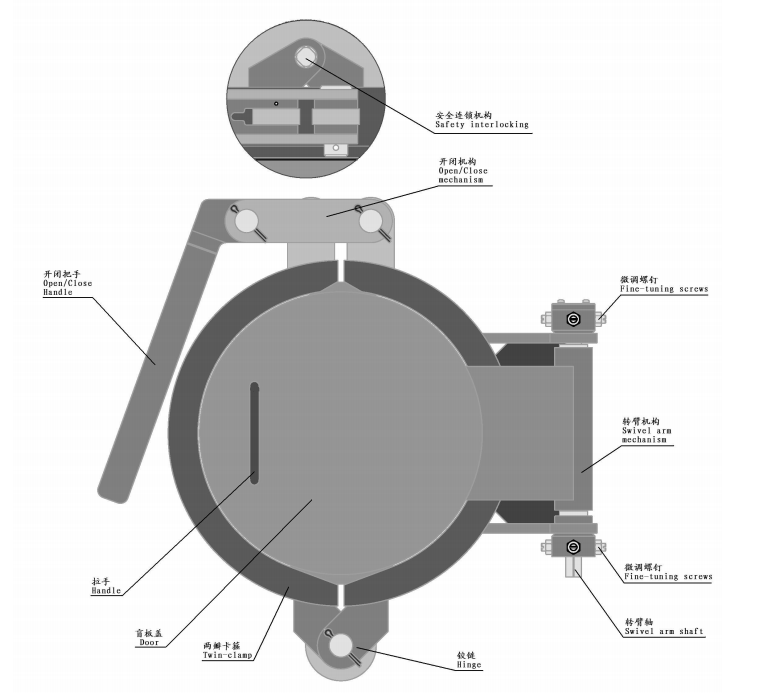

1.The Articulated type quick opening closure has a large occlusal area, high safety and reliability, simple operation, easy to open/close ,and is more suitable for installation and use on diameter not more than 32" equipment. With safety interlock mechanism to fully ensure safety and reliability.

2.The Articulated type quick opening closure is mainly composed of end closure, barrel flange, double yoke clamp, safety interlock mechanism, swivel arm mechanism and opening and closing mechanism. Turning the Open/Close Handle up or down, the double yoke clamp can be opened or contracted, so as to achieve the purpose of quick opening and closing.

Download

Double Yoke Clamp Quick Opening Closure

Quick Opening Closure is widely used in natural gas pipeline, chemical industry, medicine, metallurgy and other fields, such as receiving and sending ball cylinder, tank, pressurized kettle, filtration separator, heat exchanger and other containers and equipments that need to be opened and closed from time to time.

Double Yoke Clamp Quick Opening Closure Applications

1. All kinds of pipe cleaner receiving/transmitting devices

2. Filter, filter separator

3. Vulcanization tanks, pressurized kettles

4. All kinds of quick-opening pressure vessels

Heilongjiang Lianerdun Petrochemical Equipment Co., Ltd. Which is located in the beautiful scenery "south-China-type scenery" - Mudanjiang City, Heilongjiang Province. Since its inception, the company has always adhered to the business philosophy of "quality-oriented, customer first" and strives to become a benchmark enterprise in the industry. The company has strong technical force, complete licenses, and modern standard workshop, covering a total area of 13,000 square meters, the total number of more than 130 people, 25 technicians, complete manufacturing and testing equipment, quality control system is perfect. The technical research and development team is professional, the main technical indicators and performance of the products has reached the domestic advanced level, and the industry is in a leading position.

Double Yoke Clamp Quick Opening Closure Opening Operation

1)Before opening the door,the pressure inside the equipment must be ensured to be zero,and safe operating procedures must be strictly followed.

2)unscrew the safety bolts on the Locking mechanism. If there is residual pressure in the equipment, should stop removing the safety bolt immediately and recheck the equipment pressure again. Ensure that the inside pressure relief is complete (the pressure gauge pointer on the equipment returns to zero) before unscrew the safety bolt and locking mechanism.

3) Trigger the opening and closing handles , so that the double yoke clamps slowly rise to the maximum, to reach the end closure can be opened state, hold the handle to open the end closure.