Quick Opening Closure For Shell And Tube Heat Exchanger

Brand Lianerdun

Product origin Mudanjiang

Delivery time 30-60days

Supply capacity 100Pcs/Month

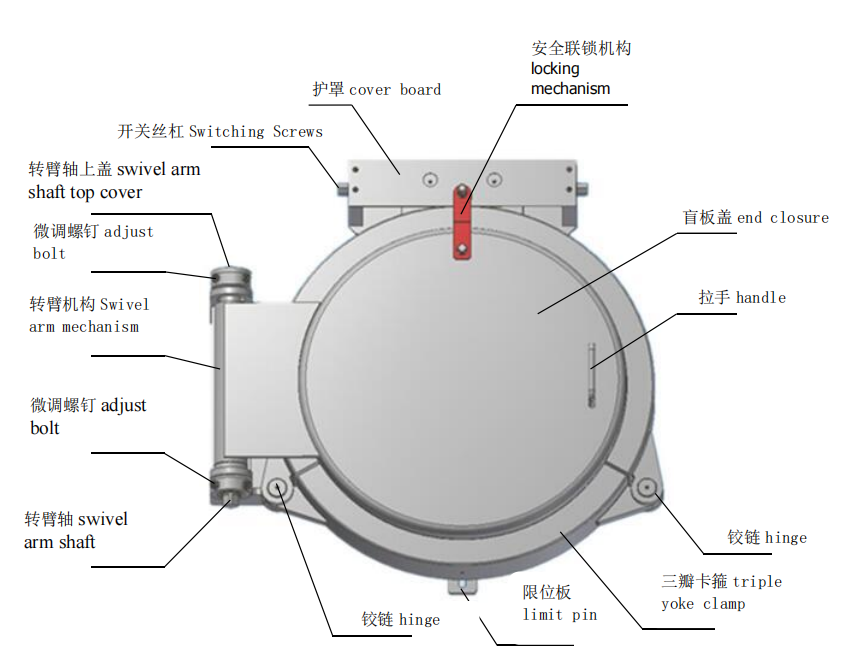

1.Triple yoke clamp type quick opening closure has a large occlusal area, high safety and reliability, simple operation, and is more suitable for high-pressure and large-diameter equipment installation and use. With safety interlocking mechanism, fully ensure safety and reliability.

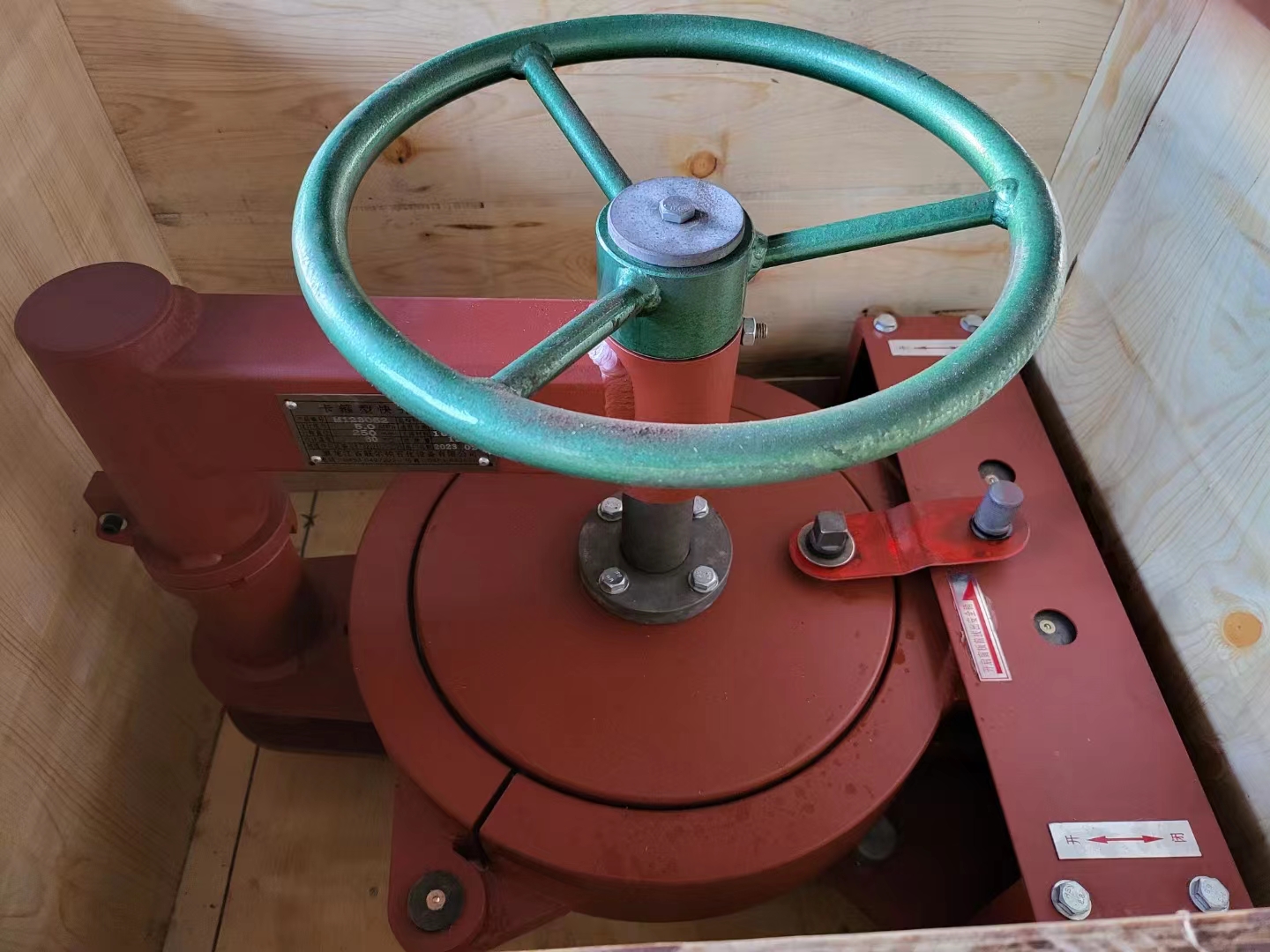

2.Triple yoke clamp type quick opening closure mainly consists of end closure, barrel flange, Triple yoke clamp, safety interlocking mechanism, arm mechanism and opening and closing mechanism. Use a special wrench to turn one end of the switch screw clockwise or counterclockwise, the Triple yoke clamp can be opened or contracted, so as to achieve the purpose of rapid opening and closing.

Download

Quick Opening Closure For Shell And Tube Heat Exchanger

Quick Opening Closure For Shell And Tube Heat Exchanger Product Information

Product Information | |

QOC Nominal Size | From 4″ to 78″ |

QOC Design Code | ASME VIII Div. 1 |

QOC Design Pressure Rating | Up to 100MPa |

QOC Design Temperature (min/max) | -46°C / +350°C |

QOC Orientation | Horizontal/Vertical |

Gasket Seal | O-Ring/Lip seal |

Design Conditions | |

Design Code ASME VIII Div. 1 | Yes |

Code stamped | Yes |

Vassel Wall Thickness | Acc. to the vessel |

Principal Materials | |

Hub Material | Carbon steel/Stainless Steel/Duplex/Super Duplex |

Door Material | Carbon steel/Stainless Steel/Duplex/Super Duplex |

Gasket Seal | NBR/HNBR/VITON |

Hinge/Davit Material | Carbon Steel / Stainless Steel |

Quick Opening Closure For Shell And Tube Heat Exchanger Package